Position:Home>Innovation&Service>Tires Knowledge

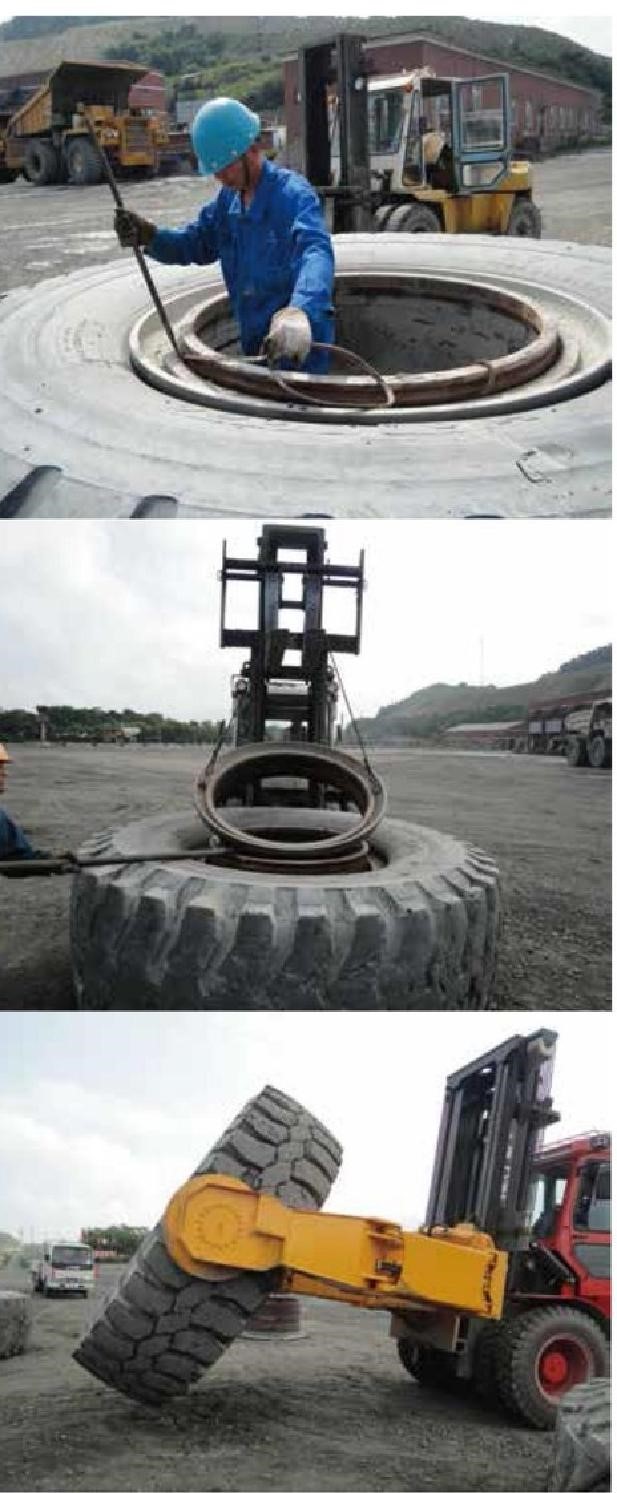

Cautions for tyres transport by forklift:

☞Put the tyre vertically across the fork;

☞Use a round fork with diameter not smaller than 15cm;

☞Square holders may damage the tyre tread, and it's forbidden to insert a flat fork inside a tyre.

When lifting tyre by crane:

☞Using the nylon or rubber sling through the hook;

☞The hook should be strong enough (with at least 15cm diameter) to protect the tyre thread;

☞Do not insert the hook in tyre bead directly for transportation.

Warning:

Haian company reminds you that all tyre transport should be operated only by the trained workers using specialized tools according professional procedures. If you fail to comply with these procedures, it may result in fault position of the tyre and/or rim, and cause the big accident.

Before Mounting:

☞Clean all components of the tyre, rim and valve;

☞Remove the packages and inspect all parts of tyre and rim. Completely cleaning of dirt and corrosives, especially in the grooves;

☞For each tyre replacement, new O-ring are requested;

☞Tyre replacement should be operated on designated tyre bay to make sure the rim parts are load stable and even;

☞Keep the tyre internal clean and dry.

Mounting Steps:

☞Firstly make sure no cracks&deformation of rim,flange and the lock ring,clean the components;

☞Fix the rim stable on the brandreth;

☞Clean the rusty on the rim (Keep grooves in lock ring and seal ring very clean);

☞Replace the valve seat and seal ring and make sure the air tube are unblocked;

☞Evenly oil the rim;

☞Clean any dusty or water inside the tyre;

☞Paint the rim oil on the beads.

☞Put the tyre onto the rim base and cap the flange on the tyre;

☞Clapse the pressing ring and press it in line with the out surface;

☞Put the seal ring into the groove(Note: Do not touch the real ring by hands if you find the ring wasn't inserted completely, but you can use crowbar);

☞Ensure the lock ring hammered in the groove of lock ring.

Inflating:

☞DO not leave O-ring or components on the tyre when inflatio;

☞Make sure all components are fitted correctly before inflation;

☞All inflating procedures should be operated within safety zone where there is protective fence to avoid the hazard of tyre burst or air tube burst;

☞Never sit on or stand in front of tyre or rim. Serious hurt even dead may occurs if the parts fly apart with explosive force;

☞Never attempt to weld or fire on or near a tyre/rim assembly. Heat from these activities may result in explosion of tyre due to sharp rising of pressure.

After Mounting: Checking the air-tightness between tyre & rim

☞Ensure every parts below are tight enough: inner liner, bead seat, O-ring, valve stem and valve cap;

☞Place the tyre horizontally and the lock ring upwards, then insert the soap water into the groove of the rim.

Precautions before Demounting:

☞ Make sure there's no air in tyre before removing any components such as nuts, rim clamps, etc;

☞ Open the valve stem to make sure all air is exhausted;

☞ Insert a steel wire to the valve stem to make sure it isn't blocked.

Demounting Process:

Process: Lock rim-bead seat band-side ring-rim Base

☞ Slowly put down the tyre with a crane after demounting;

☞ Insert the lever between the lock and bead seat, pry the lock to get a gap around it;

☞ Pull out the lock ring with the crow bar;

☞ Remove the O ring;

☞ Insert hook jack between bead seat and side ring, and jacked a gap;

☞ Fasten the two tops of bead seat band with a steel wire, then hand it out with forklift;

☞ Remove the flange;

☞ After removing the bead, turn the tire over with the crane and remove the rim.

| Tyre Size | Deviation Limit | |

| Outer Diameter | Circumference | |

| Rim Dia≥49inch | ≤24mm | ≤75mm |

Process of measuring tyre dimensions on truck:

☞Firstly, check the tyre inflation is standard or not;

☞Secondly, measure whether the dual diameter is the same, by placing an angled square across two tyres as Fig. 1, or tightening the cord of two tyres like Fig. 2.

★Notice:

☞For safe driving, it's strictly forbidden to mount radial tyre and bias tyre together;

☞Never mount the repaired tyre or retread tyre in front position;

☞Please rotate the front tyre to the rear position when the tread wear over two thrids of its OTD.

"Cold"pressure means the standard tyre pressure when tyre temperature is the same as ambienttemperature

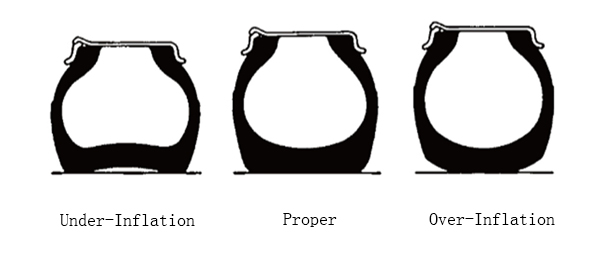

In order to get the best performance, the tyre must be kept with the suitable inflation. Both over-inflation and under-inflation will shorten the tyre running life, also may cause the malfunction.Proper inflation depends on the vehicle, ground conditions, load, speed and other factors.

Results of Over-inflation:

☞Increase ground contact pressure at the center of the tread, causing excessive wear there;

☞Reduce protection of the cord against shock from uneven road surfaces, resulting damage caused by cuts or shock;

☞Excessive pressure is exerted on the beads, increasing the potential of beads bursting;

☞Easy to slip and uncomfortable riding.

Results of Under-inflation:

☞Accelerate leakage, generate heat, which leads early tyre scrap;

☞Tread separates from cord fabric, cord fatique is accelerated, leading to broken cord;

☞Sidewalls become susceptible to rupture;

☞Tread wear is uneven and radical cracks develop;

☞Rim splits, creating air leaks in tubeless tyres.

Inflation with Air or Nitrogen:

☞Inflation with air is the most common method, it's also suitable for most applications. Attention that the compressor must have sufficient output 43m2/h and a minimum pressure of 12kgf/cm2;

☞Nitrogen can be used depends it's a kind of incombustible gas, it makes no air in tyre when inflation, which is greatly reduce the potential risk of combustion and explosion.

★Note:

☞It's normal that pressure rise due to heat build-up,different tyre has different rising pressure. If heat generated during operation results in a rise of 25% or more in inflation pressure, the cold inflation pressure should be rechecked. If the cold inflation pressure shows to be correct, either truck speed or load must be reduced. Otherwise, overheat may cause tyre separation;

☞It's forbidden to deflate air to lower the internal pressure during tyre running. Reducing inflation pressure will cause the internal temperature rise leading to tyre failure;

☞Inflation pressure should be checked and calibrated periodically;

☞Valves should always be capped, this keeps mud and dust out of the valve core and protects the air seal.

| Phenomenon | Resulting Damage |

| Higher heat generation inside tyre | Heat separation |

| Increased abrupt braking | Chipping,Bead damage,Shortening tyre life |

| Sharp cornering | Irregular wear,Quick abrasion,Bead damage |

| Frequent collision with obstacles on the road | Cutting, Cut-impact break,Punctures |

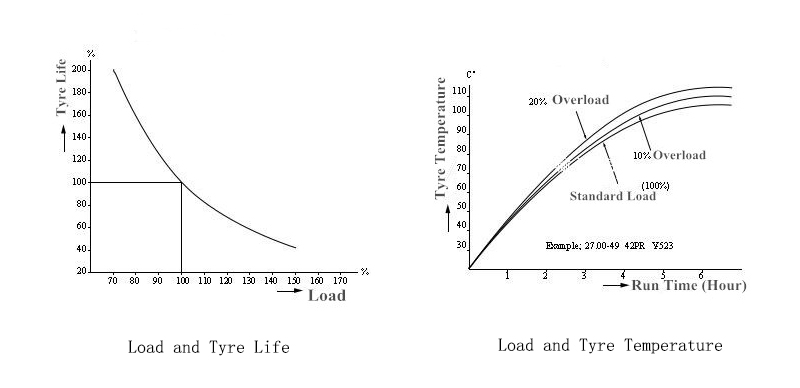

Results of Overloading:

1.Generate excessive heat and cause heat separation;

2.Excessive tyre deformation causes broken cords;

3.Rapid wear due to excessive tread movement against road surface;

4.Bear ring failure due to excessive bead movement;

5.Risk of bursting due to increased cord tension.

To avoid tyre overloading, it's also important to consider the environment factors of mine site,like the conditions of mine diggings area, and according to the load sheet provided by tyre user,the material should be evenly distributed on the truck.(see the left Fig.)

Correct Distribution

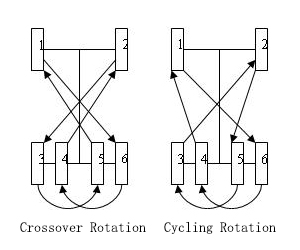

Tyre Rotation:

☞Change the tyre position in time is one of the key points to increase the tyre life;

☞When the tyre used for a period of time, the tread wear on different parts will be different due to the road chamber, brake position and fitted position. This will lead to uneven tyre wear. So it is important to rotate the tyre to make each tyre bear the same load. This is to solve the uneven wear of tyre and increase the tyre life;

☞There are two major methods for rotation, cross over rotation and cycling rotation. When you choose a method, you should rotate tyre to the end and never change the method during the rotation.

★Note:

☞For the tyres in one truck, you can choose any method above;

☞For the truck with old and new tyre, it is recommended to fit the new one in front position. For the used tyre, it is advised to fitted in rear position and rotation within rear four positions;

☞When one tyre changes the rolling direction after rotation, you should change the tyre position and adjust to the opposite way. This is to decrease the uneven wear, reduce the part tread fatigued and increase the tyre life;

☞The tyre used in rear position won't be rotated to front position.

The mine site are prone to transport more and run faster to rise its output. Inevitably, tyre internal temperature will rise due to heavy loading. Tyre has heat-resistance limitation, it is essential to define a rated load. Tyre should run under operated conditions to avoid high temperature.

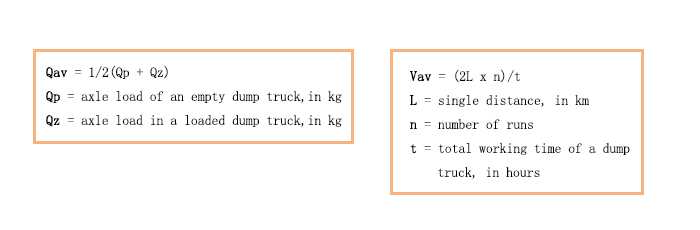

Working capacity of OTR tyres is calculated by"ton-kilometer per hour"(TKPH):

TKPH=Qav x Vay

Qav= average tyre load =1/2 [(empty truck)+(loaded truck)] in kg

Vav= average working speed =[Circle distance X number of round trips] / Total working time, in km/h

If the ambient temperature is higher than 38℃, the formula for TKPH calculation should be adjusted as following,

TKPH nom

TKPH = ————————————

1 + (Ta – Tnom) *0.0096

Example for the calculation of maximum working capacity:

TKPH of tyre 27.00R49(E-4)

Load of a dump truck

| Load per tyre (kg) | Front axle | Rear axle |

| Empty Truck | 14480 | 8500 |

| Loaded Truck | 25320 | 25320 |

Average tyre load

Qav = 0.5(14480+25230) = 19900(kg)

Average working speed of a dump truck, km/h

Average tyre load

Qav = 0.5(14480+25230) = 19900(kg)

Average working speed of a dump truck, km/h

2L × n

Vav. = ————

t

Average working speed of a dump truck, km/h

V= 6.45×52/24=13.975

TKPHnom=19.9×13.975=278

Considering the ambient temperature, we should revise TKPH as below formula if necessary.

TKPH=TKPHnom /[1+(Ta-Tnom) ×0.0096]

If the rated TKPH of 27.00R49(E-4)is 350, it is suitable for operating in above working condition because the tyre’s TKPH(=350) is greater than the real site TKPH(=278).

Road maintenance is one of the most important factors to determine the tyre lifetime, bumps, check holes, rocks and so on will cut or wear the tyre, even will cause tyre bursting. It's particularly important to maintain road in loading and dumping area because the damage in these area is more. Not only the maintenance staff but also each staff at site has the responsibility to clean the obstacles on the road.

| No. | Road condition | Damage type for the tyres |

| 1 | Dropped loaded material on roads. | Cuts,punctures,fissures of the carcass in the cut place. |

| 2 | Road improperly graded,with large bumps. | Non-uniform wear of the tread,fissure of the carcass due to high dynamic loads resulting from wear,heat damage of tyres. |

| 3 | Width and turning radius lower than standard, too long road grade,and grade larger than standard. | Cuts,non-uniform wear,heat damage of tyres. |

3.When the grade increases, the tyre is more likely to slip. This increase tyre wear and reduces fuel efficiency. The ideal road grade is no more than 5-6%.

Road Chamber and Lane Width:

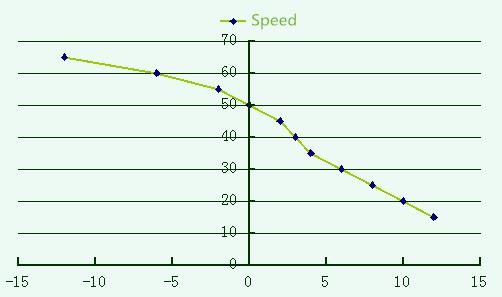

Truck speed will affect the tyre rolling radius, please follow the recommended radius and speed limit listed below:

| Recommend Radius & Speed Limit | |

| Min Radius (m) | Max Speed (km/h) |

| 15 | 8 |

| 25 | 10 |

| 50 | 15 |

| 75 | 20 |

| 100 | 25 |

| 200 | 30 |